The K3Pro product world

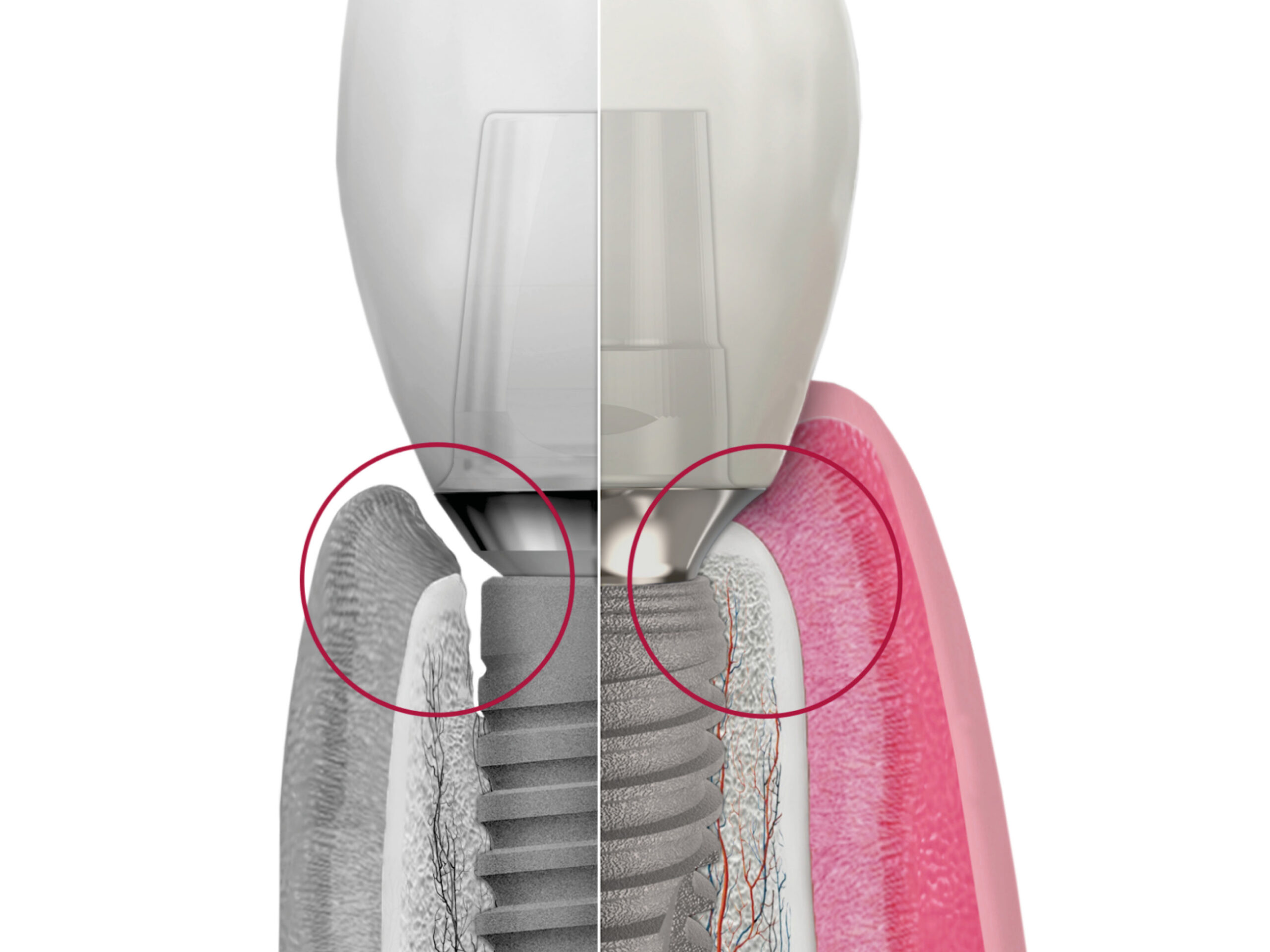

Sustainable implantologists are aware of the scientifically proven 3 mm rule with regard to the required mucosa thickness above the implant for long-term success and strictly observe this. The optimal initial situation - a 3 mm thick healthy gingiva - is generally rare, which very often requires considerable effort in soft tissue surgery for implants to be placed equicrestally. The proven, subcrestally placed and bacteria-proof K3Pro from Argon with its well-known outstanding bone and gingiva preservation provides demanding implantologists and patients with the necessary security, even under the most difficult conditions.

Only K3Pro delivers the performance of a "real" cone connection

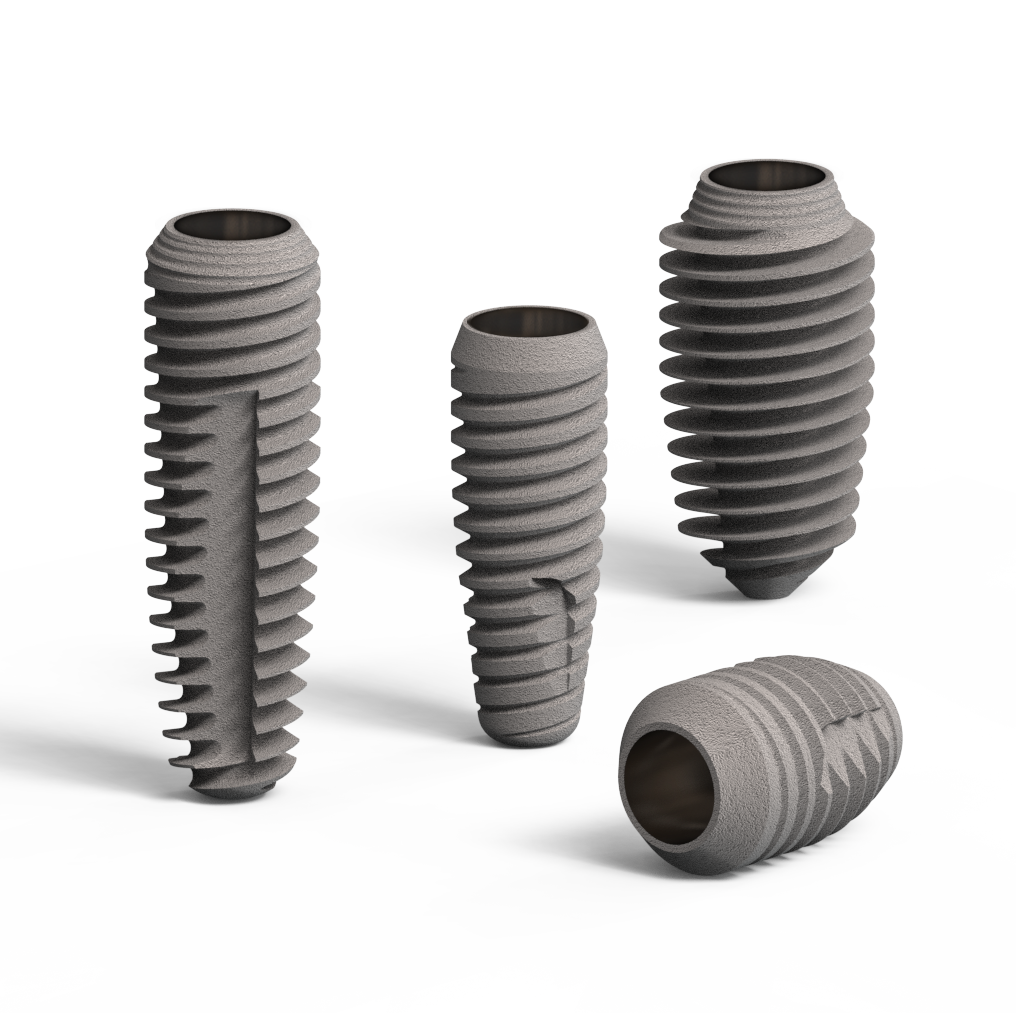

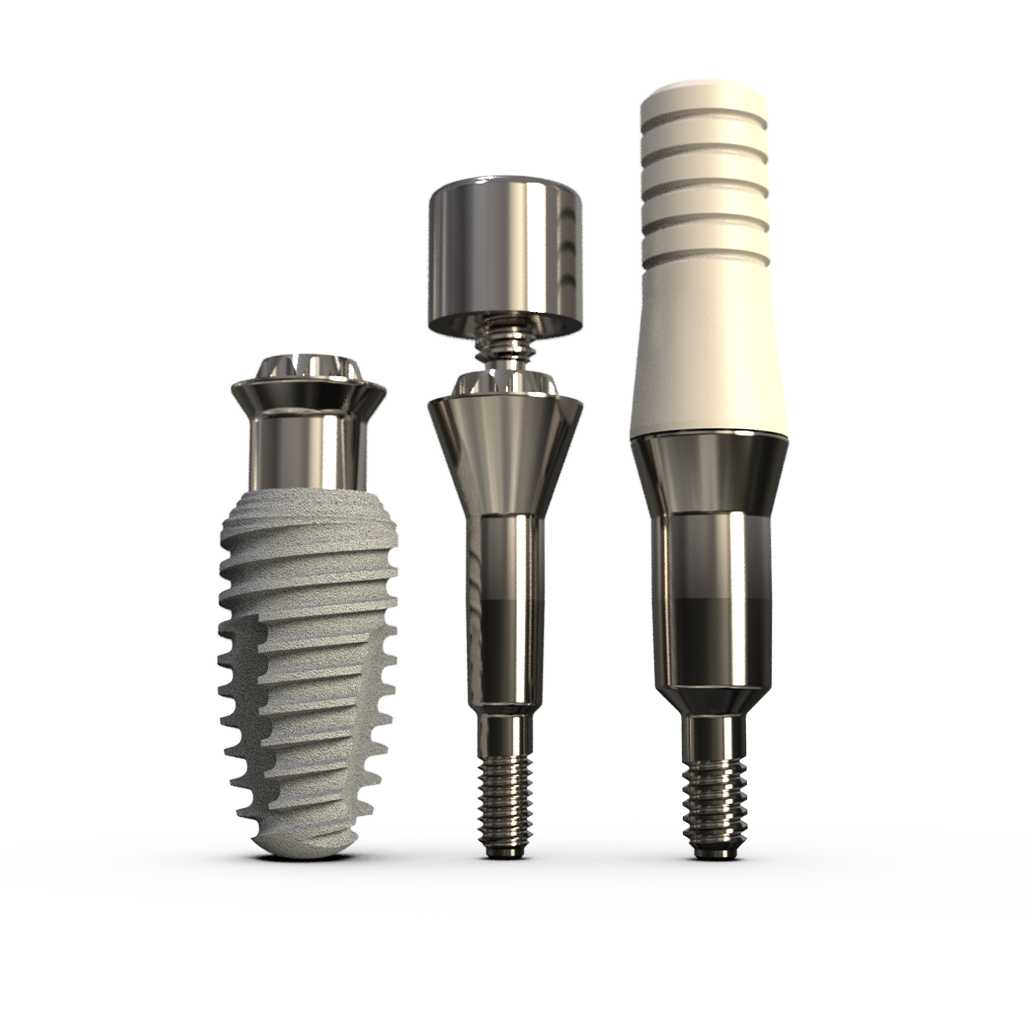

It is known from mechanical engineering that a true taper, the so-called "Morse taper", can only be achieved with an angle of 1.5° - combined with a certain length. Here the choice in the implantology sector becomes very small. Only such a steep long taper develops so much friction that the load of the connection is no longer on the screw. The forces between the abutment and implant are perfectly balanced. The load is transferred deep into the implant and thus evenly into the bone. The positive fit is therefore also friction-locked and there is no longer a one-sided load peak with the risk of fracture of individual components - screw, abutment, implant. Micromovements between the implant components are also eliminated. K3Pro offers the unshakeable stability of a one-piece, monolithic implant system with all the unrestricted prosthetic advantages of a two-piece implant system. In the case of K3Pro, even with an outstanding selection of surgical and prosthetic options for any indication.

Our technical superiority is your advantage

To summarize, this special form of tapered connection not only achieves absolute freedom of micromovement and bacteria-tightness, but also reliability and sustainability thanks to unrivalled stability. There is also no titanium abrasion due to non-positive connections, a topic that is already the focus of much scientific attention. Another advantage is the outstanding aesthetics, as K3Pro can (and should) be placed particularly deep due to its reliable seal. A bony seal is formed over the implant shoulder, which guarantees stable soft tissue conditions at all times. The Stable Tissue Concept goes one step further. It only works with K3Pro and the innovative components of the XP Line prosthetics, which have been optimized for sub-restal insertion of ≥ 2mm. Last but not least, we have also attached great importance to the "Handling" chapter. With our unique release technology, the dentist and dental technician can release the force of the form-fit cone between the implant and abutment at any time in a particularly patient-friendly and reliable manner.

After decades of gaining scientific knowledge, oral implantology has long since outgrown its infancy as a successful form of treatment. It is time for doctors and patients to become demanding! Pure function is no longer enough, perfection in esthetics and sustainability is possible.

Experienced implantologists know: "The bone sets the tone, but the tissue is the issue". Sustainable preservation of the soft tissue requires stable bone conditions. But what happens if this is not the case? Especially if considerable damage has already occurred due to outdated, highly invasive implant systems that do not comply with the principles of biological dentistry?

The preservation of hard and soft tissue is essential for long-term implantological success in terms of both esthetics and function.

With regard to sustainability in hard tissue management, principles for preventing bone loss have been successfully established by the scientific community.

Permanent bone preservation is possible if strict surgical and prosthetic rules are observed, some of which require a great deal of effort.

At Argon Dental, we are firmly convinced that in implantology, the long-term health of the soft tissue and perfect red-white esthetics must begin deep in the cancellous bone.

subcrestal, bacteria-proof two-piece implant that anatomically matches the shape of the tooth. Delicate in the bone, but stable and strong exactly where it matters: at the implant-abutment connection.

This is the essential prerequisite for creating stable soft tissue conditions under all circumstances. We take the "Bone Loss Avoidance" principles a decisive step further:

We are Creating Stable Tissue.

Below you can see our speaker Dr. Kai Zwanzig on his way to the Stable Tisue Concept:

K3Pro is micromovement-free and tight

A study of particular importance for the sustainability of implantological restorations was conducted at the University Hospital Frankfurt: "Detection, causes and consequences of micromovements at the implant-abutment interface" by Zipprich, Holger / Weigl, Paul / Lange, Bodo / Lauer, Hans-Christoph. The majority of multi-unit implant systems use a clearance-fit joint design between implant and abutment. The clinical relevance of a highly and cyclically loaded implant-abutment connection is considered to be high. This is because two-piece implant systems dominate the market due to their prosthetic advantages. In addition, increased technical failure of the implant-abutment connection is observed with unblocked single crowns in the posterior region. In addition, crestal bone resorption often occurs after abutment assembly at the implant-abutment interface if the positioning is crestal or subcrestal. The aim of an in vitro study was to evaluate the behavior of implant-abutment connections under simulated masticatory loading. Of particular interest was the recording of micromovements between the abutment and the endosseous implant body during dynamic load application. The abutments were loaded at 30° with a force of up to 200N. The force application point was 8 mm away from the implant platform and the rate of increase of the force was 0.3N/ms. The interface of the implant-abutment connection was radiographically recorded and measured using a video camera (1,000 images/s).

Evaluation of the results

The K3Pro® cone implants (4.5 mm x 13 mm) from Argon Medical Productions GmbH & Co. KG show no gap formation in the X-ray analysis, even at the maximum load of 200N. The subsequent micropump analysis also shows no penetration of a saliva-like X-ray contrast agent.

By way of comparison, it can be stated that, without exception, every classic butt joint with a purely horizontal contact surface between the implant and the abutment exhibits a microgap and a micropump effect with the same test parameters.

With conical implant-abutment connections from other manufacturers, a gap formation between the implant and the abutment can be observed with some implant systems. The Konus K3Pro® implant, on the other hand, shows no gap formation between the implant and the abutment.

Highest standards, constant control

We develop, manufacture, treat, clean and package all our components so that we can guarantee you the highest quality standards. Only selected materials and purity are considered for our implant production. Component testing is also important to us, so we check every batch for dimensions, fit and accuracy.

In addition, the surface of each batch of implants is analyzed for purity and surface structure and the load-bearing capacity of the implant/abutment connection is tested in accordance with EN/DIN/ISO 14801. We continuously check each batch to provide you with the best quality.

Osseointegration - the surface makes the difference

5 points why OsteoActive succeeds in connecting bone tissue and implant in a pioneering way:

Roughness

Roughness on the implant surface is important as it favors the adhesion of bone cells. A slightly rough surface provides more areas for cells to adhere to and thus supports bone growth.

Surface

A surface with many micro- and macrostructures, including so-called undercuts, creates excellent properties to enable fast and safe osseointegration. The patented process ensures consistently excellent surface properties.

Purity

Maximum purity of the implant surface to prevent the entry of unwanted particles and foreign substances during implantation.

implantation.

Biology

The best biocompatibility of the implant surface is achieved through careful selection of materials, manufacturing processes and surface treatments. This enables us to achieve high compatibility with gentle tissue integration.

Stability

Short healing times and the particularly tissue-friendly surface promote colonization by osteoblasts - a resilient fusion that guarantees resistance and functionality in equal measure.

Quickfinder products:

Implant occlusions

The K3Pro portfolio offers various options to positively influence the biology during healing and to anatomically optimize the subsequent prosthetics. Simultaneous augmentation for implant placement is also possible thanks to the subcrestal philosophy. Find out more here.

Transfer and laboratory components

Of course, K3Pro offers you transfer components for manual open and closed transfer as well as digital scanning intraorally and in the laboratory. In addition to the classic analogs, discover a revolutionary two-part system that considerably simplifies dental work.

Instruments & Accessories

High-precision, modular systems that can be customized according to your requirements and the thread designs and lengths you use. Clear, durable and in one place!